Samartex | The Leading Wood Processing Company In Ghana - Main Component

Kostas

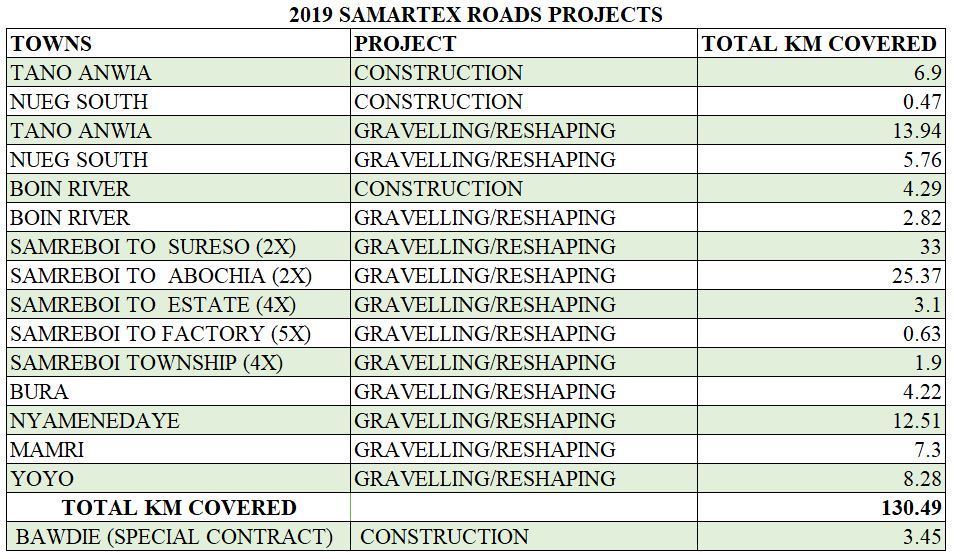

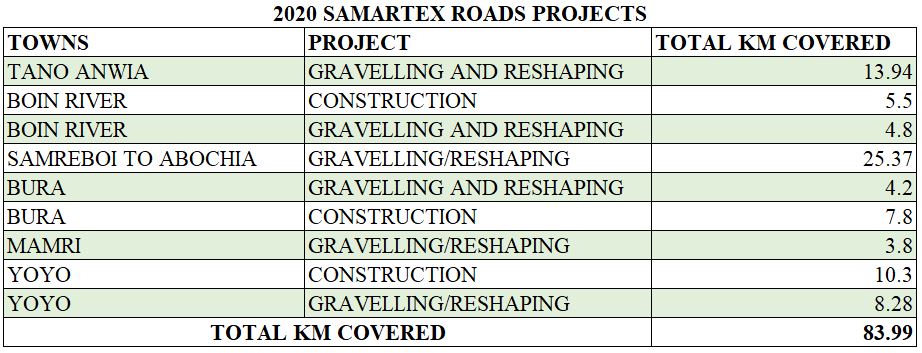

OPERATIONAL AND PUBLIC ROADS CONSTRUCTION AND MAINTENANCE

- A population of over 400,000 people benefits from Samartex constructed and maintained road network eg. Samreboi to Dadiesoaba, Dadiesoaba to Sureso, Samreboi to Abokyia, Abokyia to Nyankoman, NHyankoman to Amowie, Mile4 to Anguzu, Yiwaboa Nkwanta to Tetteh Junction, Amoaku to Ohiamatuo, Freetown to Accra Village, Hyamennae Congo. Also pothole filling on roads such as Sureso to Manso Amenfi

- Totaling 160kilometers. Cutting across three (3) districts, an annual estimated cost of between GH¢ 1,000,000 and GH¢ 1,300,000 is required and used in maintaining this road network

- Jobs carried out include:

Scarification

Reshaping and Gravelling

Pot Holes Filling

Chip-sed

Pushing and Formation

Bridge and Culverts Construction and Repairs

|

|

|

| Aboi Nkwanta Before | Aboi Nkwanta After | |

|

|

|

| Tano River Steer Bridge collapsed State before | Tano River Steer Bridge collapsed State After | |

|

|

|

| Samreboi Town Project: Before | Samreboi Town Project: After | |

|

|

|

| Pensanom Amuni: Before | Pensanom Amuni: After | |

|

|

|

| Bisaaso Bride: Before | Bisaaso Bride After | |

|

|

|

| Abochia Road: Before | Abochia Road: After | |

INDIA WOOD 2016

IndiaWood2016, is one of the world’s largest biennial woodworking event bringing together market leaders in furniture production, woodworking machinery, tools, fittings, accessories, raw materials and woodworking related products sector to participate in a unique international display of competence.

In 2014, the event gathered 32,703 woodworking professionals who networked, sourced their product requirements and created millions worth of business possibilities.

In 2016, the 9th edition of IndiaWoodwill be held from February 25 to 29 at the Bangalore International Exhibition Centre (BIEC). Leveraging the success of its previous editions, over 650 leading global companies from 40 countries are expected to participate showcasing their latest technology, innovation and product offerings to a projected 40,000 attendees from across the globe.

The show floor of IndiaWood 2016 will span over 40,000 square meters of woodworking solutions, machineries, materials and components. The exhibitors will be categorized into machinery and non-machinery profiles and will be in dedicated halls.

INDIAWOOD is the biggest sourcing platform for furniture manufacturers, wood based handicraft manufacturers, saw millers, craftsmen, woodworking professionals, architects and interior designers in the region.

Over the last decade, PDA Trade Fairs & EUMABOIS, in partnership with exhibitors and visitors have catalyzed the growth of the Indian woodworking industry. IndiaWood continues with its tradition of being a profitable business partnership for the Woodworking Industry where demands and solutions meet together.Samartex will be participating at Hall 3 -H3UL B262 Stand in a very prominant place.

We will be exibiting our products from Ghana

Rotery Veneers

Sliced Veneers

Lumber

Square Big Beams

We hope you all will come and see us and our products ....

DELHI WOOD SHOW 2017

The Indian woodworking and furniture manufacturing industry is pegged at a massive $ 20 billion in size and employs more than 3,00,000 people in the organised sector. The furniture sector in India makes a marginal contribution to the Gross Domestic Product (GDP), representing about 0.5 per cent of the total GDP. On a per capita basis, the market is still under penetrated compared to more matured markets.

The Indian furniture Industry is valued at being the 14th largest furniture market in the world driven largely by the increasing income levels and influence of global lifestyle trends making the wood and furniture industry one of the most attractive investment opportunities.

In spite of furniture manufacturing in India undergoing transition, around 60% of the furniture is imported from other countries. Hence, the scope for machinery companies to capitalise on this demand-supply gap in India is high. In the machinery segment, the industry has potential to grow in the product groups like solid and panel wood processing, finishing lines, tools and accessories etc. Apart from the above, major investments in particle board, MDF manufacturing, laminates have been made in the recent years in India and these materials and value added products also offer huge opportunity for both national and international companies.

While the wooden home furniture is the biggest segment, the fastest growth is seen in the modular furniture and the kitchen segment. The industry has seen a compounded annual growth of 30%.

The current e-retailing boom also offers immense business opportunities to the entire eco-system.The entering of international and national players like Amazon, PepperFry, UrbanLadder, Flipkart, Snap Deal,etc has raised the benchmark for quality in the furniture industry.

The non-machinery segment also has high prospects to attract more international companies from the product segments like fittings, hardware and structural parts, function and components, lighting systems, lights, electrical fittings for furniture production and Interior designing, raw materials, timber and lumber, materials for furniture production, semi finished products for cabinets, office and modular furniture.

In order to conserve forests, cutting of soft jungle wood has been banned by the Indian Government and this offers wide opportunity for timber exporters from other countries to enter the Indian timber trading market. Already our woodworking shows are represented by various International timber councils like American Hardwood Export Council, American Softwood, French Timber, Canadian Timber, Malaysian Timber council, etc. With more than 67+ countries already exporting sawn timber and wood based materials to India this product segment will attract more international companies to India. According to the Department of commerce, in the year 2014 – 2015, India has witnessed an import of USD 225 million in this product segment. Samartex will be a participant on this event . We invite youall to see our products in our stall on 1st to 4th March 2017.

Bottom Slider 1 - Social Responsibility

Our Team

Board of Directors

| Mr. Kurt Ditz | - Chairman |

| Mr. Philip Brown | - Member |

| Mr. Edward Prah | - Member |

| Mr. Fosuaba Banahene | - Member |

| Mr. Richard Duah Nsenkyire | - Member |

| Mr. Kweku Brenu | - Secretary |

Top Management Team

| Mr. Richard Duah Nsenkyire | - Managing Director |

| Mr. Ransford Quaidoo | - General Manager |

Extended Management Team

| Mr. Armin Dubnitski | - Technical Director |

| Mr. Thomas Gyimah | - Human Resource Manager |

| Mr. Vincent Beble | - Assistant HR Manager |

| Mr. Upali Katuwawalage | - Chief Engineer |

| Dr. Charles Miezah | - Chief Resident Medical Doctor |

| Dr. Tijani Yussif | - Resident Doctor |

| Mr. Francis Hemene | - Civil Engineer |

| Mr. Philip Adzrah | - Deputy Transport manager |

| Mr. Justice Eshun | - Forest Co-ordinator |

| Mr. Fritz Osei-Amoah | - Forest/Roads Operations Manager |

| Mr. Kelly Smith | - Head of IT & MIS |

| Miss. Christina Nkoom | - Hospital Administrator |

| Mr. B. M. Piyathilake | - Maintenance Engineer |

| Mr. Nii Adjei Tawiah | - MIS Manager |

| Mr. Raymondo Dialuang | - Mouldingmill Manager |

| Mr. Nelson Amelordi | - Plantations Manager |

| Mr. Douglass Amponsah | - Plymill Manager |

| Mr. Fredrick Yeboah | - Veneer Maintenance Manager |

| Mr. Clement Densu | - Plymill Maintenance Manager |

| Mr. Peter A. Atampugre | - Power House Manager |

| Mr. Evans Amoakoh | - Production Co-ordinator |

| Mr. Jesus Gonzales | - Roads Manager |

| Mr. Solomon Angate | - Sawmill Manager |

| Mr. Jeonard Vecillas | - Sawmill Maintenance Engineer |

| Mr. Richard Arkoh | - Sawmill Maintenance Manager |

| Mr. Clifford Infante | - Stores Manager |

| Mr. Andrews Kofi Amani | - Takoradi Office Manager |

| Mr. Ganesh Yandamuri | - Transport Co-ordinator |

| Mr. Isaac Tuffour | - Veneermill Manager |

| Mr. Samuel Asamoah | - Veneermill Maintenance Manager |

| Mr. Daniel Fobil | - Workshop Manager |

Forest Policy

FOREST POLICY

Almost the whole of Samartex’s concessions takes the form of what is known as ‘Forest Reserves’. These are areas of forest, which have been demarcated and set aside to be safeguarded for silvicultural use.

In other words, they are protected from farming activities or any other activities which would destroy the forest canopy. Commercial timber extraction is allowed in these reserves but under strictly controlled and monitored conditions. Some reserves are completely protected from all commercial activity (although none of the Samartex concessions are), and within almost every reserve some areas are completely protected from logging activities. This protection can be to protect rivers, extreme slopes, etc. Large swathes of many reserves have also recently been designated as ‘Globally Significant Biodiversity Areas’ (GSBAs) and set aside from all future logging activities to maintain the complex interdependent number of species both plant and animal. Productive forest reserves (or the productive portions of these reserves) are subdivided into compartments (usually 128 ha).

These ‘compartments’ are the smallest management units, and harvesting is carried out within the confines of these compartments. The compartments in the reserves are grouped according to a harvesting schedule. The principle of this schedule is to manage the reserve on a forty-year rotation. This means that when a compartment has been logged it will be a further forty years before any further commercial logging can occur. These forty years have been chosen as the optimum period to allow natural regeneration to occur after logging. The individual compartments are grouped into coupes within the harvesting schedule. Each coupe lasts for five years. The company is allowed to log the compartments within five years.

The next coupe cannot be entered into before the five years have elapsed. The company cannot simply log the compartments on an ad-hoc basis. Apart from the harvesting schedule, there are furthermore detailed controls on the logging activity at the compartment level. It is a commonly held misconception that tropical logging is simply clear-cut felling where vast areas are deforested. Nothing can be further from the truth. Ghana’s logging standards are some of the strictest in the world. The number of trees removed per hectare (<2) is extremely small. Indeed, by European or North American forestry standards, it is tiny. Every tree that the company can take is individually selected, and the logging operations themselves are strictly controlled and monitored by the Forest Services Division. Before any logging activity can commence, a stock survey team from Forest Services Division (FSD) surveys the entire compartment. Every commercial timber tree larger than 50cm diameter is recorded, as well as the physical features and topography within the compartment. This survey also demarcates the compartment boundaries by slashing a clear line through the forest to delineate the extent of the compartment. It is a vast undertaking, usually taking a team of eleven people up to four weeks.

Agro-Forestry And Afforestation

Agro-Forestry

- Aside from employing over 2,000 workers from across the country, Samartex through its support, training, and alternative livelihood programs provides jobs directly and indirectly to a number of communities:

- Sensitizing and training communities and farmers on best farming practices

- Distribution of beehive boxes for farmers interested in beekeeping and harvesting, pig farming assistance, purchasing of thaumatin fruits from farmers, snail rearing, seedlings distribution to farmers, interplanting agreement with farmers, etc.

Regeneration Of Our Natural Resource

- Our nursery in Samreboi where timber seedlings are raised.(available for distribution and purchase)

- Tano nimre plantation

- Oda kotoamso (ocap) plantation

- Adeiso plantation

These are all directed at regenerating and sustaining our natural resource

Mission & Vision

To achieve a sustainable balance

Between human and ecological needs of all aspects of society that interacts with our activities and deliver operational excellence in all facets of our business by conducting it in a more sustainable manner to promote the well being of our shareholders, employees and other stakeholders.

Social Responsibility Agreement (SRA) and Corporate Social Responsibility

Social Responsibility Agreement

- Act 547(section 3E, section 20), LI 2254, section 11(D) provide the legal framework for the implementation of the SRA. Timber and wood processing industries are required to pay 5% of stumpage to beneficiary communities which are all within a 5km radius of our operational areas.

- Samartex was already making such payments to fringe communities before the implementation of a more formalised and streamlined social responsibility agreement in 2004.

CORPORATE SOCIAL RESPONSIBILITY

It should be noted that aside from fulfilling all legally required financial obligations to the government and traditional institutions within its jurisdiction, Samartex goes beyond providing services and other benefits to various communities

As a responsible cooperate citizen Samartex is committed to fostering mutually beneficial relationships with the communities it operates in not only within the context of the law of the host jurisdiction but also within the confines of policies that cover all facets of good corporate citizenship. Our employees are encouraged to play an active role in community affairs.

Samartex has an ambitious vision for corporate social responsibility to ensure our responsible account of our economic, social, and environmental impacts based on the following policies: -

About Us

Samartex Timber & Plywood Company Limited was

established in 1995

Hitherto, the company was known as African Timber & Plywood Company (AT&P) which had been in existence since 1947 under the UAC group of companies. Samartex Timber & Plywood Company Limited took over AT&P at a time when it was saddled with a myriad of problems including mismanagement and a disastrous fire outbreak, which had left the company’s facilities in chaos.

Products

Our products are all sourced from controlled wood managed natural forests.

Samartex is sourcing the raw material from forests, which are known for centuries to provide the best quality of tropical forest wood.

Our Saw Mill has an installed capacity of 2,500m3, Moulding Mill 450m3, and Ply Mill 1,200m3.

Our modern veneer plant produces up to 1.000.000m2 veneers per month. When it comes to veneer production, two essential factors are most influential on the quality of the product: the experience and knowledge of the people who process the veneers and a sustainable supply of the highest grade of logs.

Having put in place a system that ensures the continuous development and education of our human resource based on one of the most advanced forest management techniques.